QUALITY CREATES...

history, continuity, future... SINCE 1859

TEXTILE INDUSTRY IN THE REGION OF TWENTE

Before 1830 manufacturing of textiles didn’t play a major role in Twente. It was usually an extra activity of agricultural families in winter months when there was no work on land. With the steam engine finding its way to Twente around 1830 - and the textile industry in Twente being strongly stimulated by the state, everything changed.

New possibilities were within reach and industry began to flourish. Slowly but steady small workshops with steam engine-driven looms were expanding to larger textile factories and a big part of the population in Twente became employed in textile factories.

Source: Historische kring Losser / Steam machine

However, the major growth took place after a devastating fire in 1862, which destroyed the most part of Enschede. It was the family Van Heek that contributed greatly to the renovation of the city by building new fire-proof factories, schools and reinvesting in the city. By installing modern machinery in the factories, the production skyrocketed. Also other textile merchants began investing and around 1900 there were many new textile factories built around the reconstructed city.

Van Heek is a known textile family in Twente and was of immense value for the development of the region. In 1910 Van Heek & Co was the largest industrial enterprise in the Netherlands with 2,369 employees.

THE ORIGINS OF VAN HEEK TEXTILES

2 December 1859: Although Van Heek family played a role in Van Heek Textiles establishing in Losser, our story begins in Almelo where the company Gebroeders Scholten & Companie was founded on the 2nd of December 1859 by four brothers Barend, Gerrit, Jan Frederik and Jan Scholten. The company produced fine textile cloth, such as calico, shirting and cambric for inland sales and export, mainly to the Dutch East Indies.

Source: Historische Kring Stad & Ambt Almelo

EXPANSION OF THE COMPANY

It was evident that the World War I affected the export of textiles, yet Scholten & Companie regained their strength by expanding production lines. In 1928, a second factory complex with three divisions (weaving mill, finishing department and clothing manufacturing facility) was added in Wierden.

In the 1930s, the Scholten company was hit by the crisis. Companies had hard time to stay afloat and during the World War II, sales decreased even further. After liberation, it became clear that the Dutch East Indies market was largely lost.

Source: Historische Kring Stad & Ambt Almelo

FUSION WITH L. VAN HEEK & ZONEN

The company sought for allies, which led to cooperation with the spinning mill of L. van Heek en Zonen in Losser.

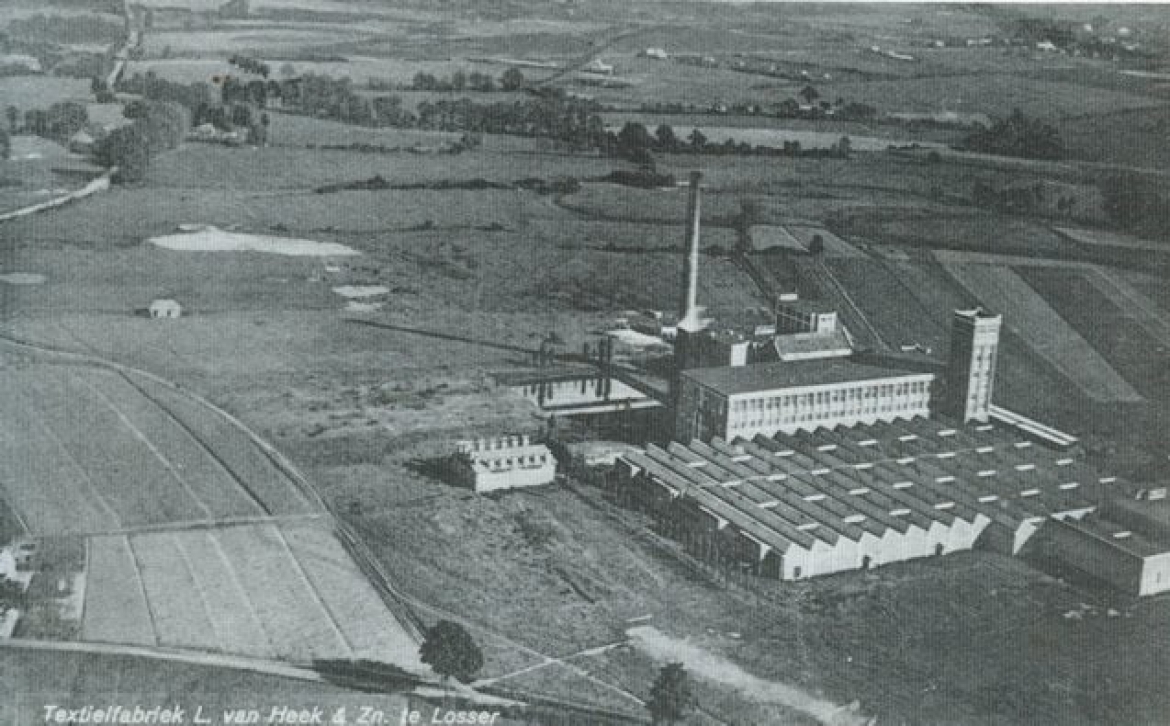

L. van Heek en Zonen was founded by Ludwig van Heek in 1926 and was originally a spinning mill that expanded its production with a weaving mill and knitting mill for the production of, among other things, bandage fabrics and net curtains. In 1962, the companies merged and this is how Van Heek Scholco came into being, as an integrated company for spinning, weaving and finishing.

In the 1980s, Van Heek Scholco was spread over three locations; in Almelo the weaving mill was situated, in Wierden the warehouse with the makeup and finishing department, and in Losser the knitting facilities and bandage manufacturing. The headquarters were at that time located in Almelo. The company could be counted among the leading manufacturers of handkerchiefs, colourfully woven fabrics for clothing, net curtains but also bookcloth.

Sources: Historische Kring Stad & Ambt Almelo / De Tijd De Maasbode 24-8-1961

LUDWIG VAN HEEK

Ludwig van Heek was the son of Gerrit Jan van Heek and nephew of Hendrik Jan and Herman Van Heek, which were the founders of Van Heek & Co. The company in Losser was established by Ludwig van Heek after a family dispute, which lead Ludwig van Heek leaving Van Heek & Co and starting a new company in Losser together with his sons.

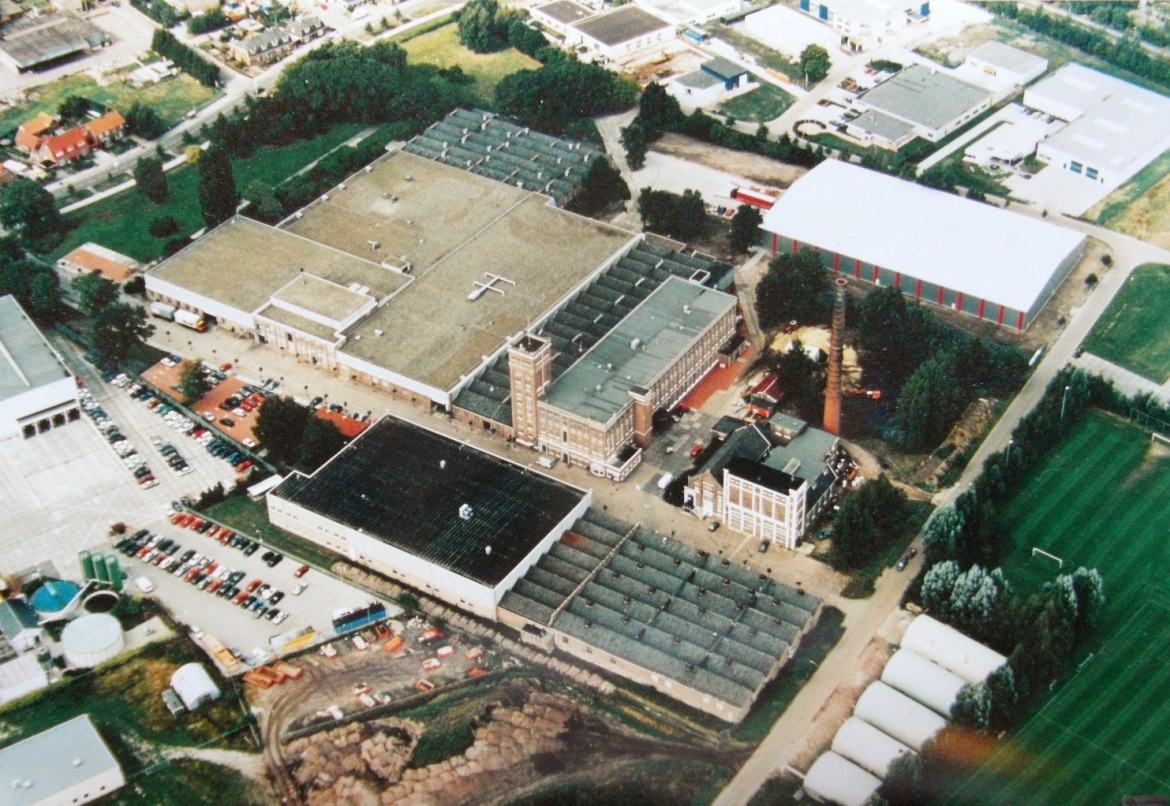

FACTORY IN LOSSER

The building that to date serves as a head office of Van Heek Textiles is one of the six textile factories in the Netherlands listed as a national monument. It is an old textile factory in every way. The water tower. The coal bunkers. The rails for the coal wagons used to run through here. It was built in 1926 by Ludwig van Heek and was meant to resemble the textile factories in Manchester. It is a complete factory as they looked 100 years ago, yet one of the few factories in the world that houses the entire production process, from weaving and knitting to dyeing, coating and finishing.

Source: Historische kring Losser

PRODUCTION & HEADQUARTERS SHIFTED TO LOSSER

When in 1987, the production as well as the headquarters shifted to Losser, the company’s name was changed to L. van Heek Textiles (official name), after the founder of the factory in Losser, Ludwig van Heek.

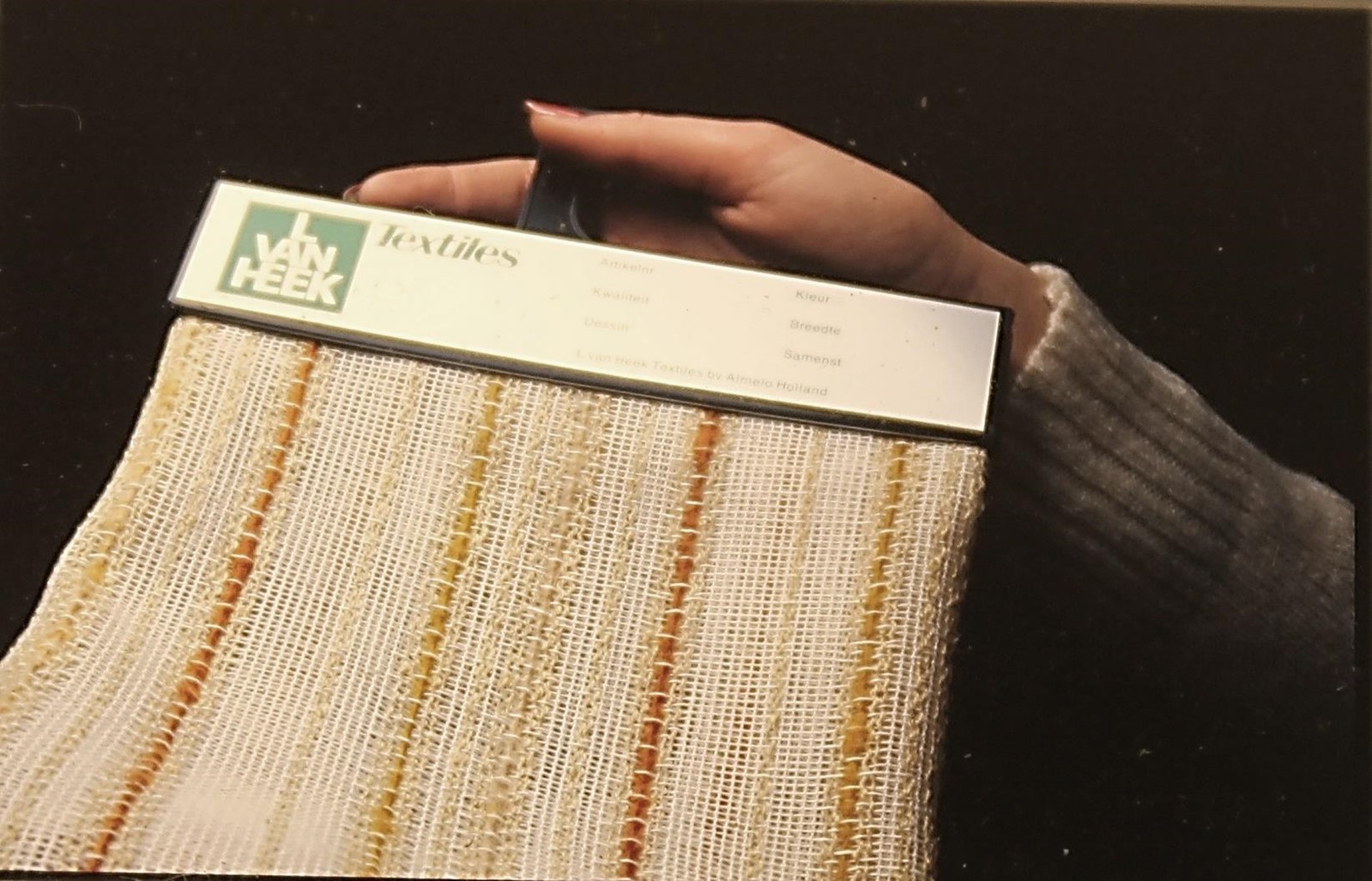

Later, the product group net curtains & household textiles was discontinued. Instead, new product lines for window decorations, technical fabrics and knits were set up. Bookcloth became the leading product group with its all-time classic Brillianta, which is to date favoured by book designers and sold worldwide.

Source: Historische kring Losser

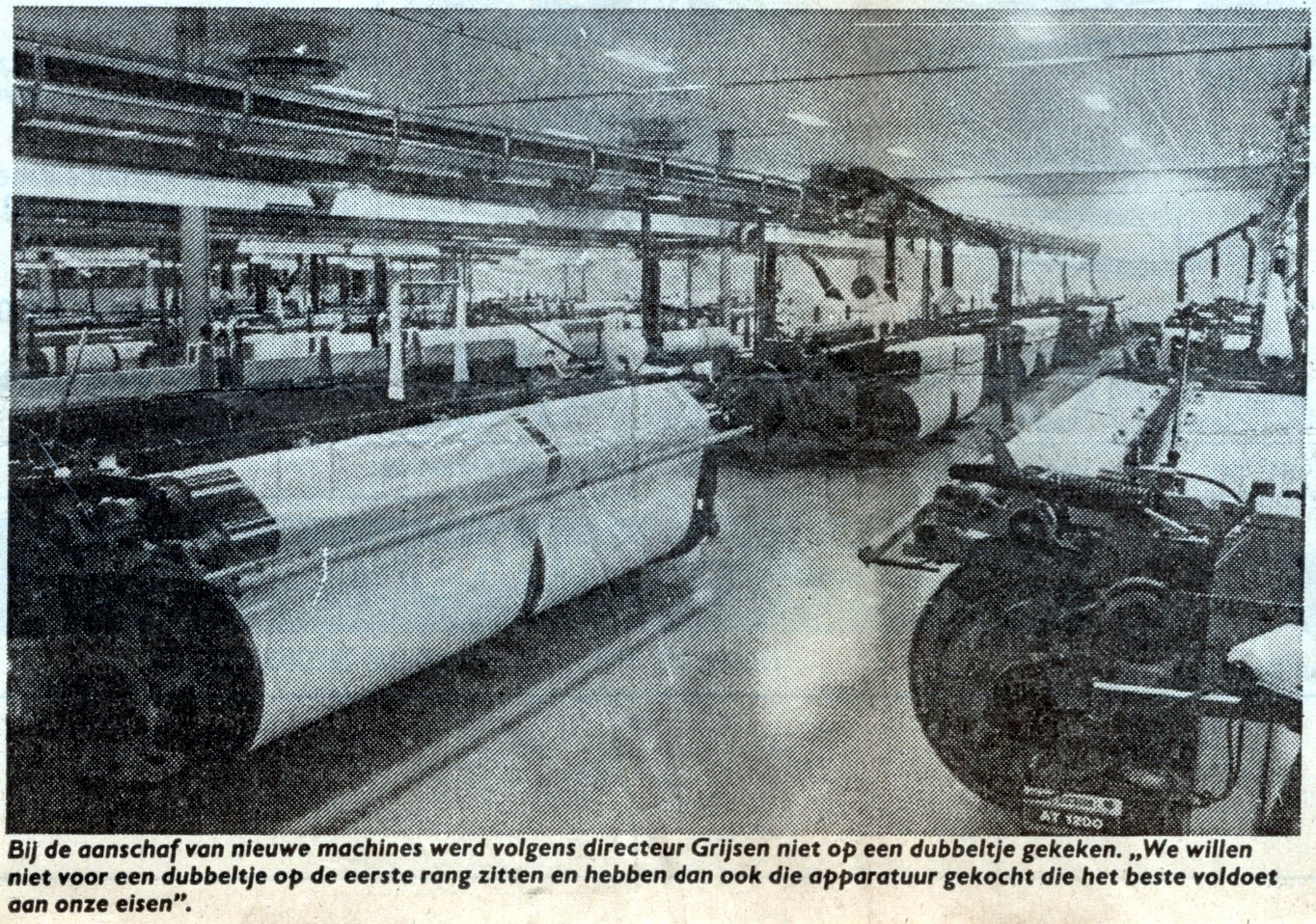

The factory houses multiple fields of specialism under its roof. The entire process of weaving, knitting, upgrading and finishing takes place in the factory in Losser, in order the materials can be bought and used by customers all over the world. Our interdisciplinary team of experts from R&D department, sales and factory works closely together to translate the international trends into new designs, colours and substrates.

With more than 100 employees, we are committed to developing and producing high-quality textile materials. Their applications are very broad, from book covers to insect screens. Do you have a book at home that is bound in textile? Then the chances are that the textile comes from our factory. But also, textile on your roller blinds, mesh in your insect screens and canvas of your favourite art print.

At least 130,000 meters of woven fabric and 60,000 meters of knitted fabric are produced per week. We strive to produce our materials in the most sustainable and circular way possible, while maintaining consistently high quality and delivery reliability. Only by offering our customers the best possible solutions, continuous innovation in products and resources, and by investing in our employees, we believe we can grow as a company.